Brushless motors are innovative electric motors that operate without the traditional brushes found in older designs. This unique mechanism results in reduced friction and wear, making them an ideal choice for various applications. From drones and electric vehicles to home appliances, the benefits of brushless motors are evident in their efficiency and reliability. This comprehensive guide is essential for anyone interested in modern motor technology and the advantages of brushless motors in today’s engineered solutions.

What Are Brushless Motors?

Brushless motors are an innovative advancement in electric motor technology. Their construction and operation diverge significantly from traditional brushed motors, enhancing performance and efficiency. Understanding the definition of brushless motors and their operational mechanics can provide insight into their increasing popularity across various applications.

Definition and Basics

The definition of brushless motors refers to synchronous motors where torque is generated through the interaction of the magnetic fields created by both the rotor and the stator. A standout feature of these motors is the absence of mechanical brushes, which typically leads to reduced wear and improved performance. Brushless motors come in several configurations, which include:

- DC Brushless Motors

- AC Synchronous Motors

- Stepper Motors

These variations highlight the versatility and adaptability present within the realm of electric motor basics, catering to diverse needs and specifications.

How Brushless Motors Work

Understanding brushless motor operation involves grasping the principles of electromagnetic induction. Unlike traditional motors that rely on direct electrical connections, brushless motors utilize electronic controllers to deliver power efficiently. This design choice allows for superior thermal management and increased efficiency during operation.

The primary components of brushless motors include:

| Component | Function |

|---|---|

| Rotor | Contains permanent magnets that create a magnetic field |

| Stator | Houses the coils that receive electrical current |

| Electronic Speed Controller (ESC) | Manages power delivery with precise voltage switching |

By controlling the voltage in the stator coils in a specific sequence, the ESC enables the rotor to spin. This process efficiently converts electrical energy into mechanical energy, setting brushless motors apart from their brushed counterparts.

Understanding Brushless Motors: A Comprehensive Guide

Brushless motors have gained significant traction across various industries due to their advanced motor technology. A key to their popularity lies in the different types available, each designed for specific applications. Understanding these types and their components can aid in selecting the most appropriate brushless motor for a particular need.

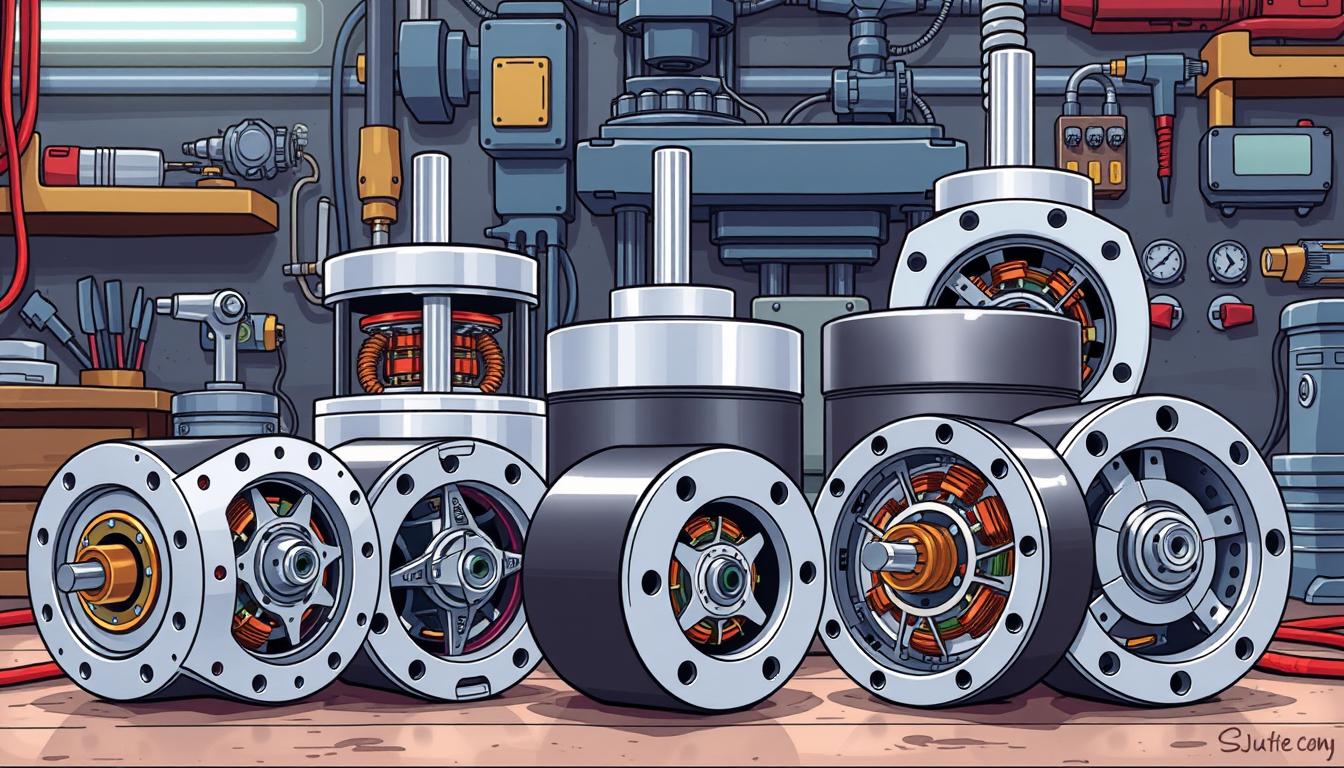

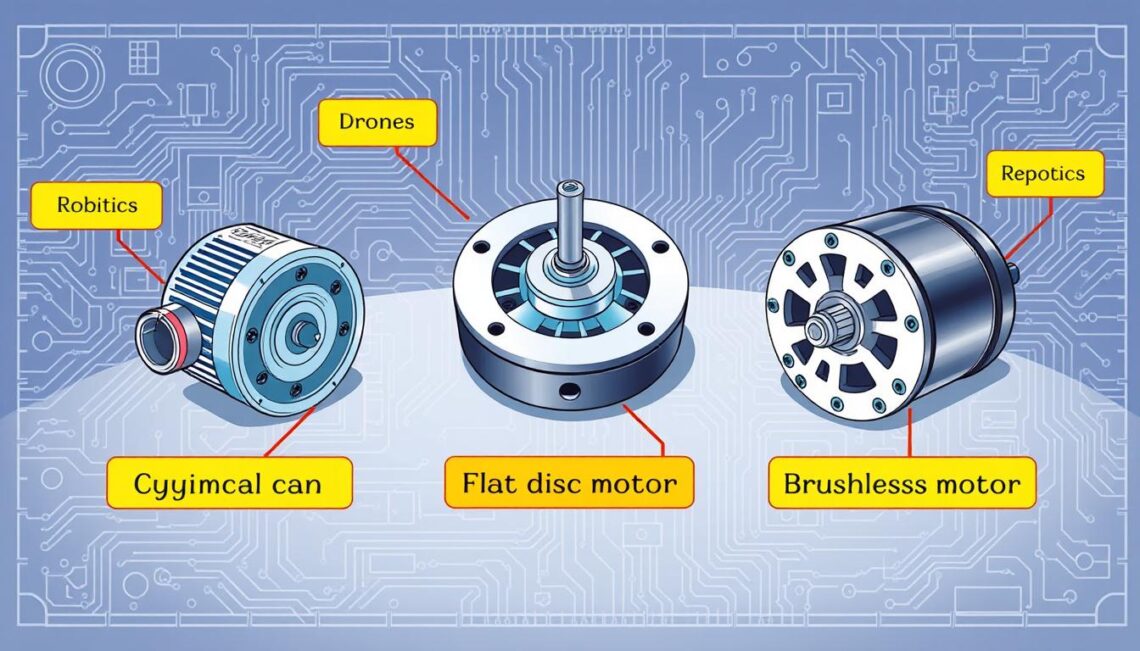

Types of Brushless Motors

Several types of brushless motors cater to diverse applications. Common categories include:

- Brushless DC (BLDC) Motors: Known for their high efficiency, these motors are frequently used in battery-powered devices.

- Permanent Magnet Synchronous Motors (PMSM): Renowned for their reliability and high torque, PMSMs excel in industrial settings.

- Brushless AC (BLAC) Motors: These motors are primarily used in applications requiring precise speed control, such as HVAC systems.

Key Components Explained

The effectiveness of brushless motors stems from their intricate components, which include:

- Rotor: Houses permanent magnets that create a rotating magnetic field.

- Stator: Contains electromagnetic coils that energize to generate rotational force.

- Electronic Speed Controller (ESC): Regulates power and adjusts motor speed based on feedback, ensuring optimal performance.

- Feedback Devices: Encoders or Hall sensors provide information to the ESC, enhancing precision in control.

| Type of Motor | Key Features | Common Applications |

|---|---|---|

| Brushless DC Motors | High efficiency, low maintenance | Battery-powered devices, drones |

| Permanent Magnet Synchronous Motors | Reliable, high torque | Industrial machinery, electric vehicles |

| Brushless AC Motors | Precise speed control | HVAC systems, robotics |

Benefits of Using Brushless Motors

Exploring the advantages of brushless motors reveals why they are increasingly becoming the preferred choice across various industries. Their enhanced efficiency and impressive durability not only optimize performance but also reduce operating expenses and maintenance efforts, making them attractive for both manufacturers and end-users.

Efficiency Compared to Brushed Motors

One of the most significant brushless motor benefits is their remarkable efficiency. Unlike brushed motors, which suffer from friction losses due to brushes, brushless motors can achieve energy efficiencies beyond 90%. This heightened efficiency of brushless motors translates into lower operational costs and extended battery life, particularly in portable devices where energy conservation is critical. Moreover, their superior thermal management reduces heat generation, enhancing overall performance.

Longevity and Maintenance Advantages

In addition to their efficiency, brushless motors are known for their impressive motor longevity. The absence of brushes minimizes wear and tear, allowing these motors to run for well over 10,000 hours before needing substantial repairs. This durability reduces the frequency of maintenance checks and aligns with the demanding reliability requirements in many applications. So, when considering the maintenance of brushless motors, it’s clear they offer a long-lasting solution without compromising on quality.